High Frequency Screen

Product Description

High-frequency screen is a device that uses high-frequency vibration to achieve fine screening of materials. Its core components include high-frequency vibration motors, screen boxes, and screens. With high vibration frequency and small amplitude, it can effectively overcome the problem of material clogging the screen. It is widely used in the classification, impurity removal or dehydration of fine and ultra-fine materials. Compared with ordinary screening equipment, it has higher screening efficiency and better accuracy, and is widely applied in fields such as mining, building materials, and environmental protection, serving as a key equipment for fine material processing.

Working principle

The working principle of the high-frequency screen is centered on high-frequency and small-amplitude vibration. It is generated by a high-frequency vibration motor or exciter, which is then transmitted through the transmission structure to the screen box and screen mesh. After the fine-grained materials fall onto the screen surface, the high-frequency vibration breaks the adhesion force of the particles, allowing the material layer to be loosely suspended and separated by size and density. The fine particles overcome the friction force and pass through the screen to form the screen bottom product, while the coarse particles are pushed by the vibration force towards the discharge end and are discharged. This achieves fine material classification, impurity removal or dehydration, effectively solving the clogging problem of ordinary screens.

Product

1. Fewer blockages and higher efficiency: High-frequency and low-amplitude vibration can loosen the materials, break the particle adhesion, and allow fine particles to pass through the screen quickly, significantly reducing blockages and improving processing efficiency compared to ordinary screens.

2. Excellent grading accuracy: It can precisely distinguish materials of different particle sizes, meeting the requirements for strict particle size control in various scenarios.

3. Strong adaptability: It can be used for dry grading, wet screening or dehydration, and is suitable for handling fine materials in multiple industries.

4. Low energy consumption and stable performance: Compact structure, low operating noise, low failure rate, and lower energy consumption than ordinary screens with the same processing capacity.

Technical Parameter

| Model No. |

Effective sieve

diameter(mm) |

Powder

(KW) |

Vibration force |

Rotary speed

(r/min) |

|

| EGPS-600 |

550 |

0.55 |

8000N |

3000 |

| EGPS-800 |

760 |

0.75 |

10000N |

3000 |

| EGPS-1000 |

930 |

1.1 |

15000N |

3000 |

| EGPS-1200 |

1130 |

1.5 |

20000N |

3000 |

| Machine can be customized based on your need |

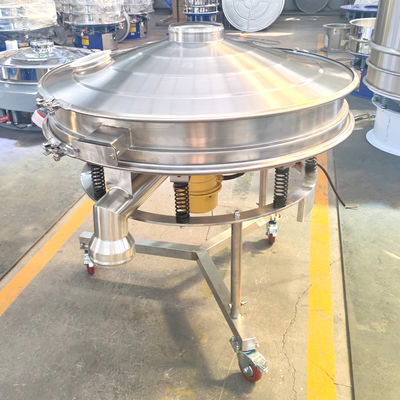

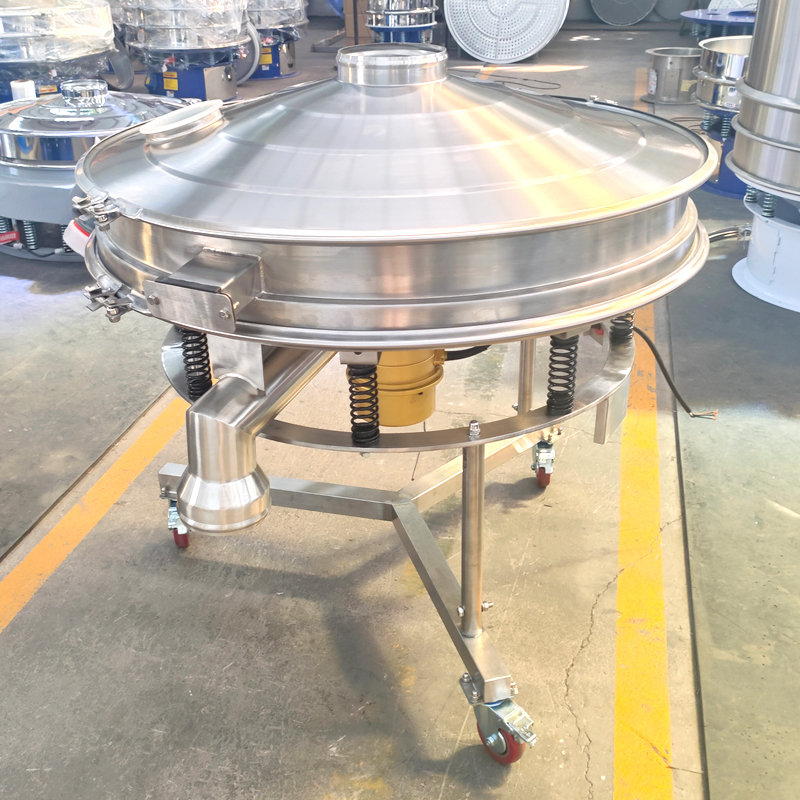

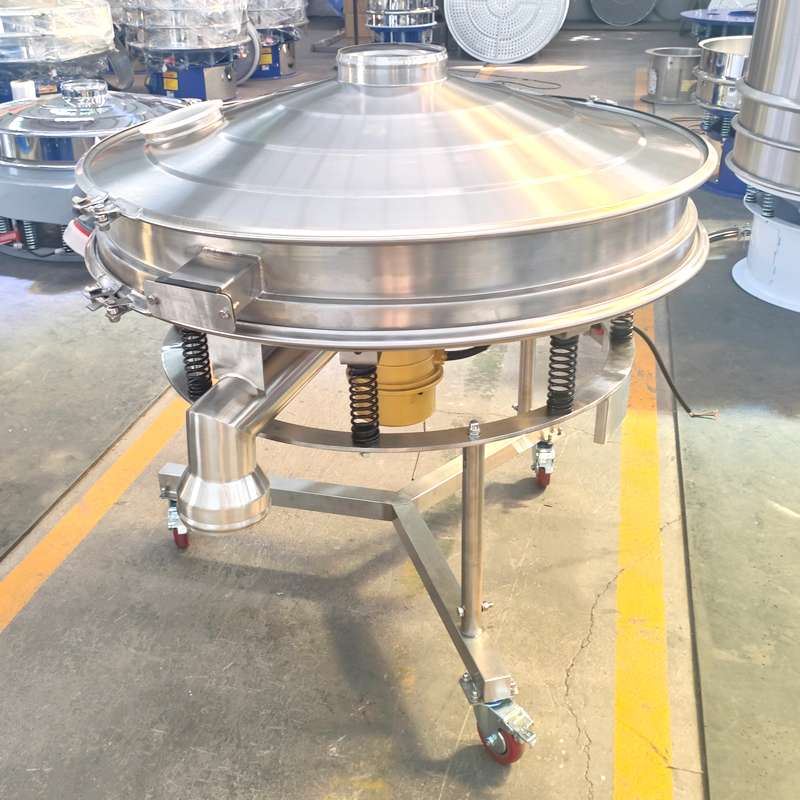

Product display

Application

The 450 liquid filter is suitable for filtration and solid-liquid separation of a variety of materials, including but not limited to the following types of materials:

1. Suspension: Filter solid particles suspended in liquid, such as ore slurry, ceramic suspension, etc.

2. Sewage treatment: remove solid particles and suspended matter in sewage.

3. Chemicals: Filter various chemicals, such as solvents, dyes, pigments, resins, etc.

4. Food and Beverages: Filter liquids such as juice, alcohol, beverages, cooking oils, etc.

5. Pharmaceutical products: filtering liquid medicine, slurry, preparations, etc.

6. Petroleum and chemical industry: filtering crude oil, liquids in the refining process, chemicals, etc.

Packaging and shipping

About us

Our factory

We have been specializing in the production of Screening and conveying equipment for 13 years. China's vibrating screen industry top three. And we have done matching and OEM for many large companies. Including the world's top vibrating screen manufacturer, Sweco, USA, we have OEM for his China region. And our products are often exported to Australia, Thailand, Indonesia, New Zealand and other countries. We welcome customers or dealers to visit our factory and will arrange everything for you.Our factory address: West of the industrial and commercial office of Da Zhaoying Town, Xinxiang City, Henan Province.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!